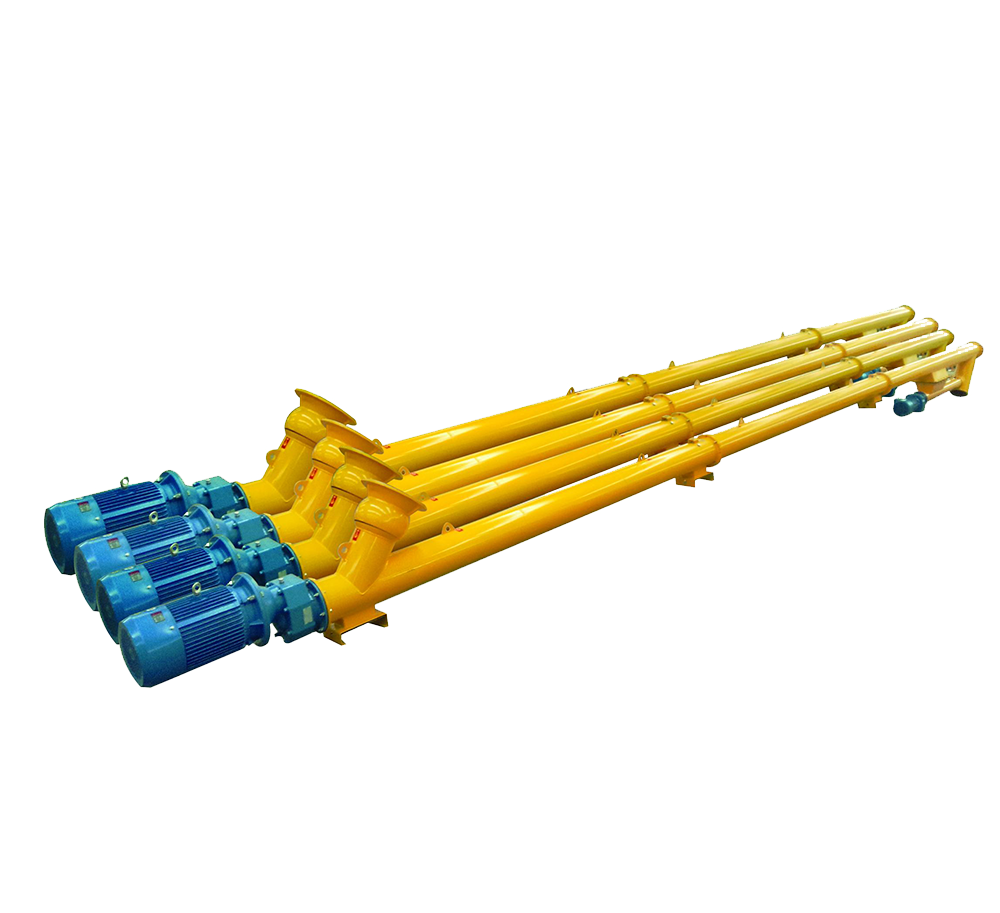

The dual screw conveyor, also known as coarse fine screw conveyor, is composed of mother screw and sub screw. The mother screw ensures fast feeding in the early stage of the weighing cycle and shortens the time. In the later stage of the weighing cycle, the sub screw works alone for micro feeding and precision measurement.