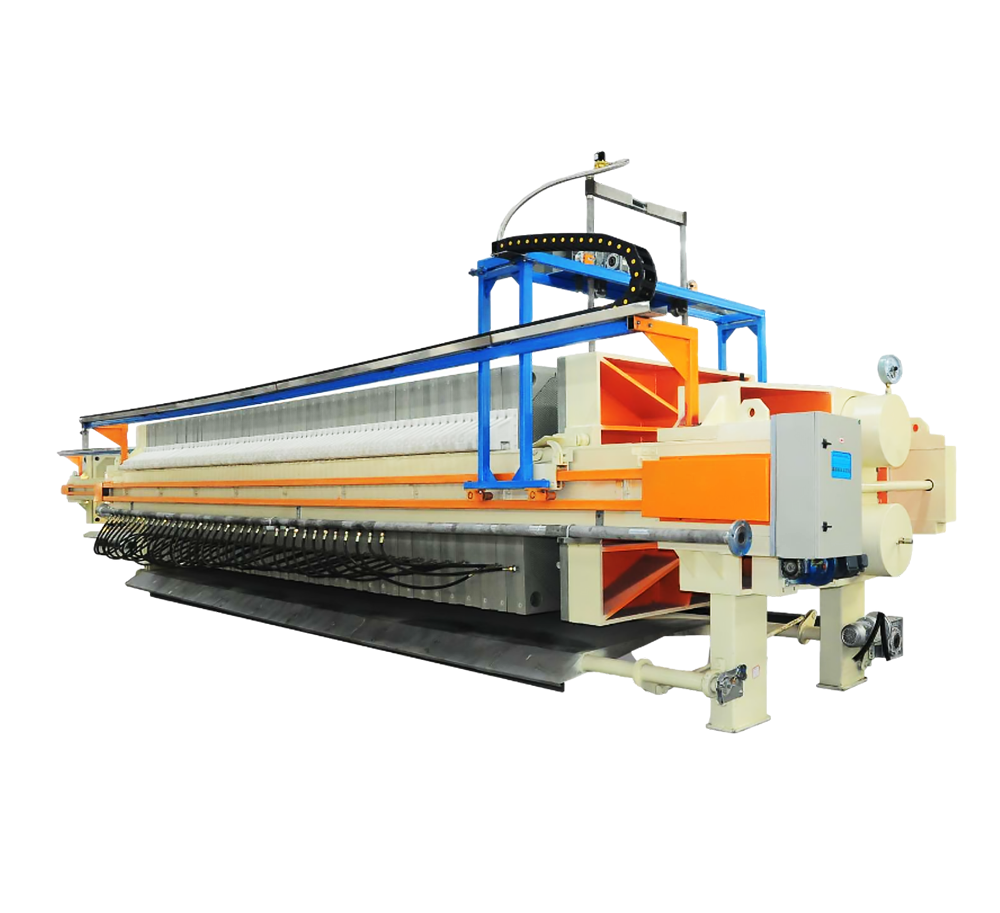

The filter press uses the pressure difference on both sides of the filter cloth to force most of the water in the material to permeate the filter cloth and flow out of the body, while the material is blocked in the filter chamber to form a filter cake to achieve the purpose of filtration. Because there is a large pressure difference on both sides of the filter cloth during the filtration process, the filtration speed is increased and the water content of the filter cake is reduced, and the special filter cloth is used to make the filtrate clear, and the filtration effect is much better than that of a vacuum filter.

search the product

return