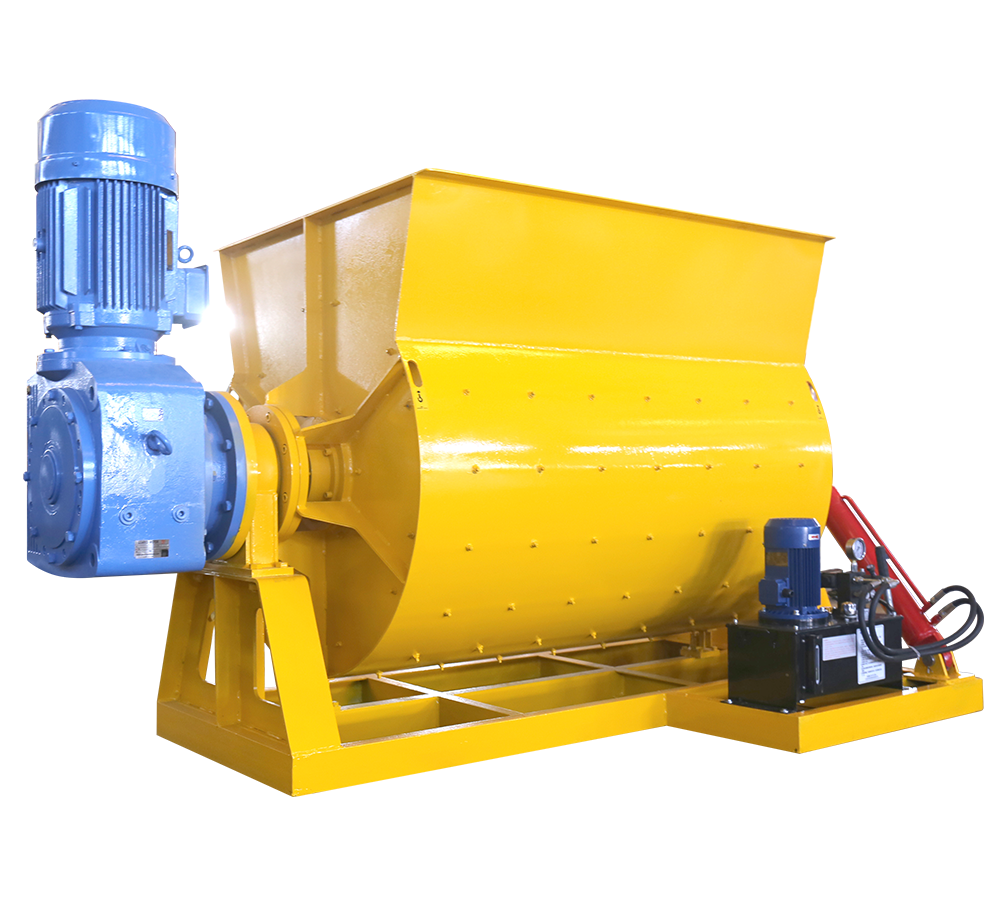

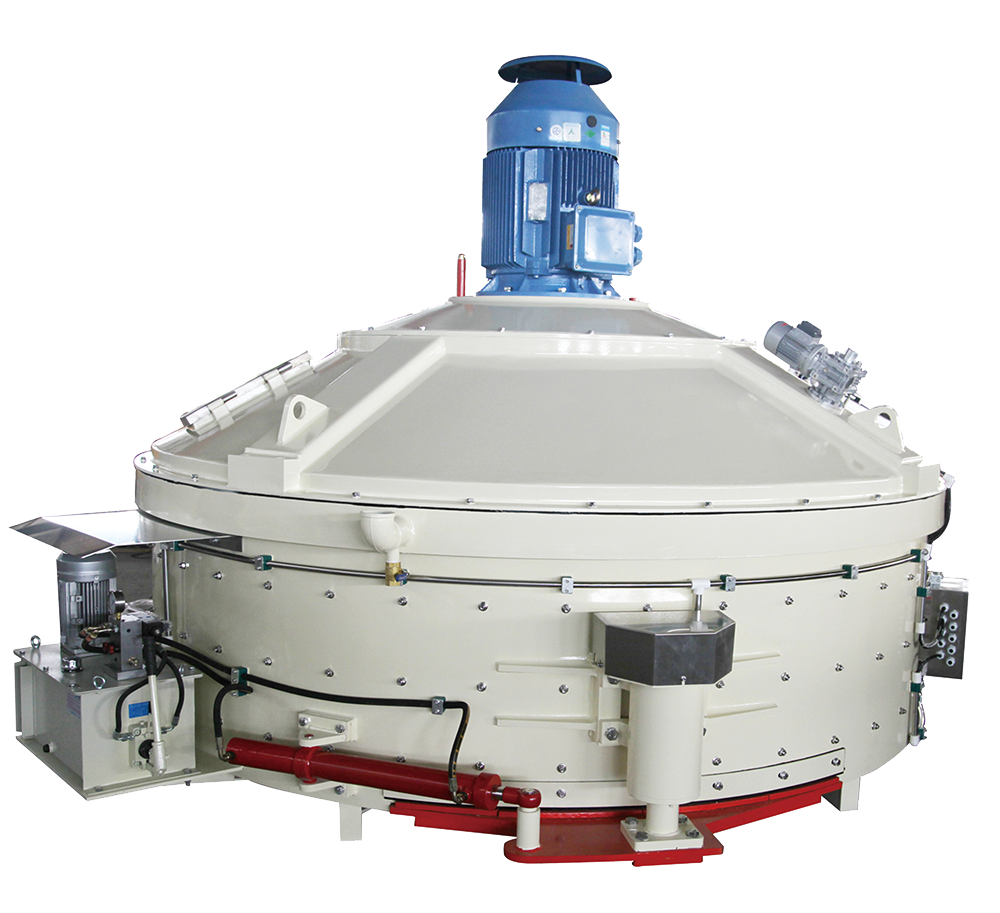

Efficient, reliable, fuel-saving, large volume, easy to maintain. The spiral blade design accelerates the overall circulation flow of the mixing material, which can not only realize the circular movement and the axial countercurrent movement, but also form a radial countercurrent movement to improve the mixing quality and efficiency of concrete.