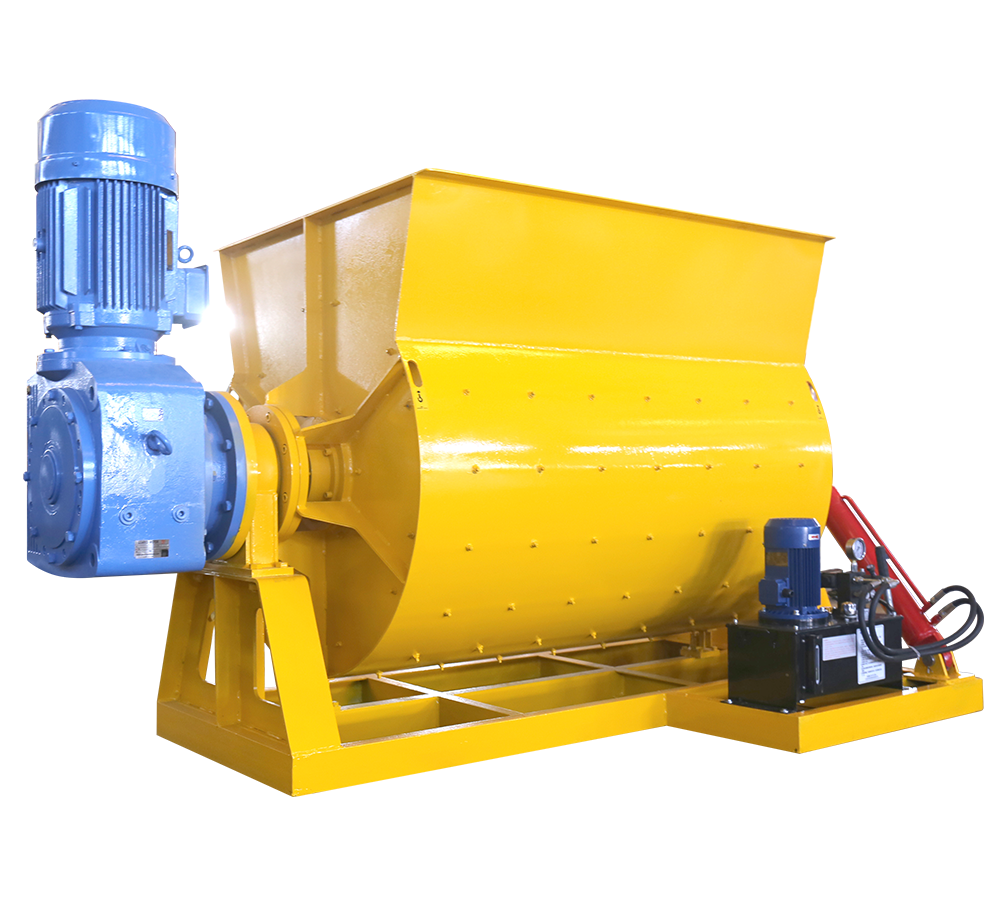

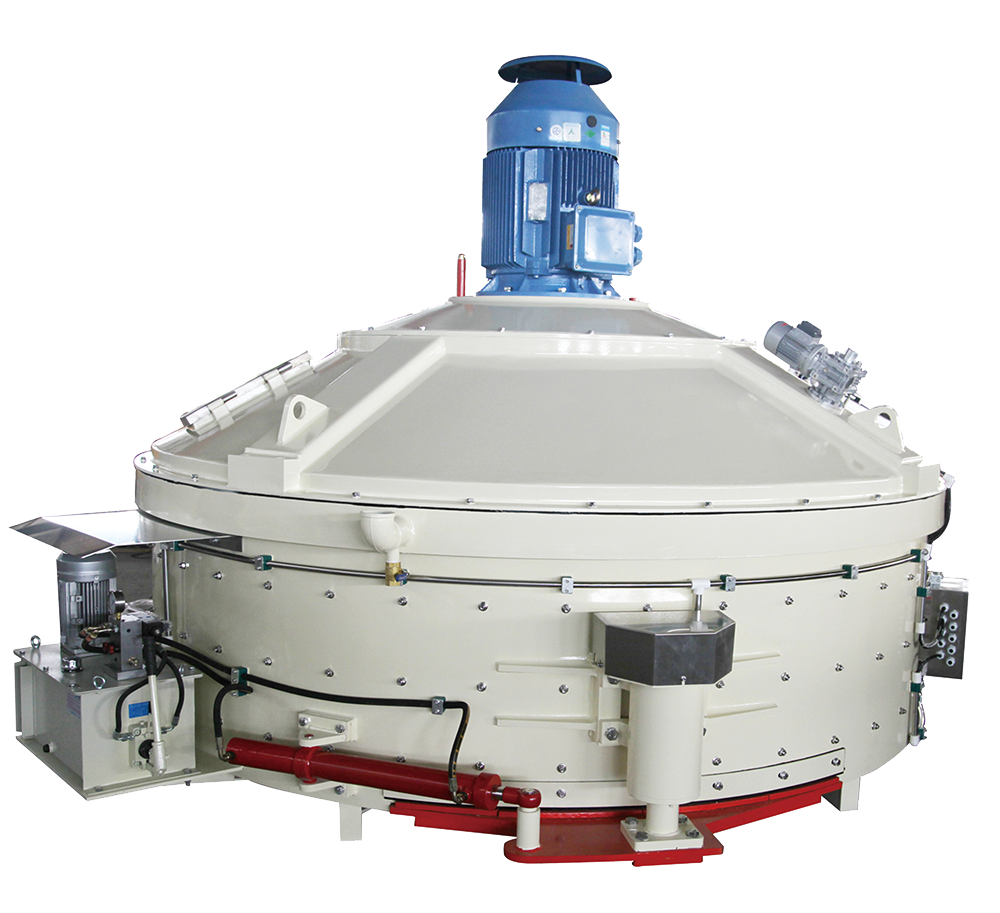

It is suitable for high-speed rail special prefabricated structural parts, pc prefabricated parts and civil engineering construction sites. The newly developed multi-motor vertical shaft mixer is suitable for high-speed rail special prefabricated structural parts, pipe piles, sleepers, tiles and other manufacturing enterprises, as well as various civil engineering construction sites and commercial concrete mixing stations.